This weekend I took delivery of my first order of panels and hardware, I spent saturday mounting the panels and making a few alterations to the MIP frame to ensure the ECAM monitor fitted correctly. I soon realised that the 19inch wide-screen is actually too narrow and actually longer than required so I will eventually switch this out for a standard 19inch monitor which should then mean I can make use of both of the upper left standby instrument windows.

After a whole day of soldering the Korry switches in the auto-brake and loudspeaker panel I managed to give them a ‘test-flight’ from Belfast (EGAA) to London Stansted (EGSS) with a greased landing rate of -131fpm 🙂 – I took various photo’s of the panels and korry LED’s in action which can be seen on the photo gallery page.

I’ve also posted a quick ‘test’ video on YouTube showing the panels and korry switches in action 🙂 – The video can be found here: http://youtu.be/Kh2Ri2Xju2w.

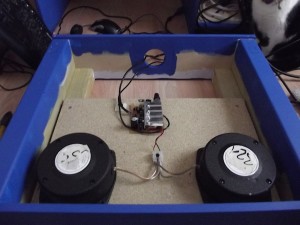

I’ve now properly configured my second PC for off-loading some of the tasks of the main FSX PC (FS-MASTER) onto a new PC (FS-CTRL1) which now runs WideFS, ActiveSky, pmSounds SIOC (all USBOutput cards are connected to this PC). Now that the Auto-brake panel and Loudspeaker panel I also tested connecting the BBI-32 card to the remote PC and to my surprise I am extremely pleased to report that you can have BBI-32 and BU0836X cards connected to a remote PC using WideFS and it still registers button presses etc on the main FSX PC… which is awesome meaning that I will now connect both you input cards and output cards to the second PC all communication with the main FSX PC is then done over WideFS. Meaning that now the only thing my main FSX PC (FS-MASTER) does is run FSX, run the four displays (external view, PFD/ND, ECAM and standby instruments) and will have the side-stick, pedels and throttle levers leaving the other tasks (Weather Engine (ActiveSky 2012), ATC (FSInn), Flight deck sounds (pmSounds), Running the USBOutput cards (SIOC) and have all the BBI-32 cards to run the MIP panel switches and the OHP switches and rotaty encoders).

More updates soon! 🙂